Purchase Order Lead Time Calculation and Reduction

Nov 24, 2023 By Susan Kelly

Customers today anticipate less wiggle room in delivery times and more personalized attention from brands. But what does this mean for your online store specifically? To avoid shipping delays and ensure that your purchases are filled correctly and promptly, you should fine-tune the lead time between placing a purchase order and receiving the goods. In this article, we'll discuss purchase order lead times and how to figure them out for your own e-commerce company.

What Is The Order Lead Time?

The time a supplier or merchant takes to complete an order is referred to as the order lead time. The order lead time is the time it takes from when an order is placed until it is fully fulfilled and delivered. Depending on the goods being ordered, the location of suppliers, and the time of year, lead times can differ widely from one industry to the next.

How Do Lead Times Work?

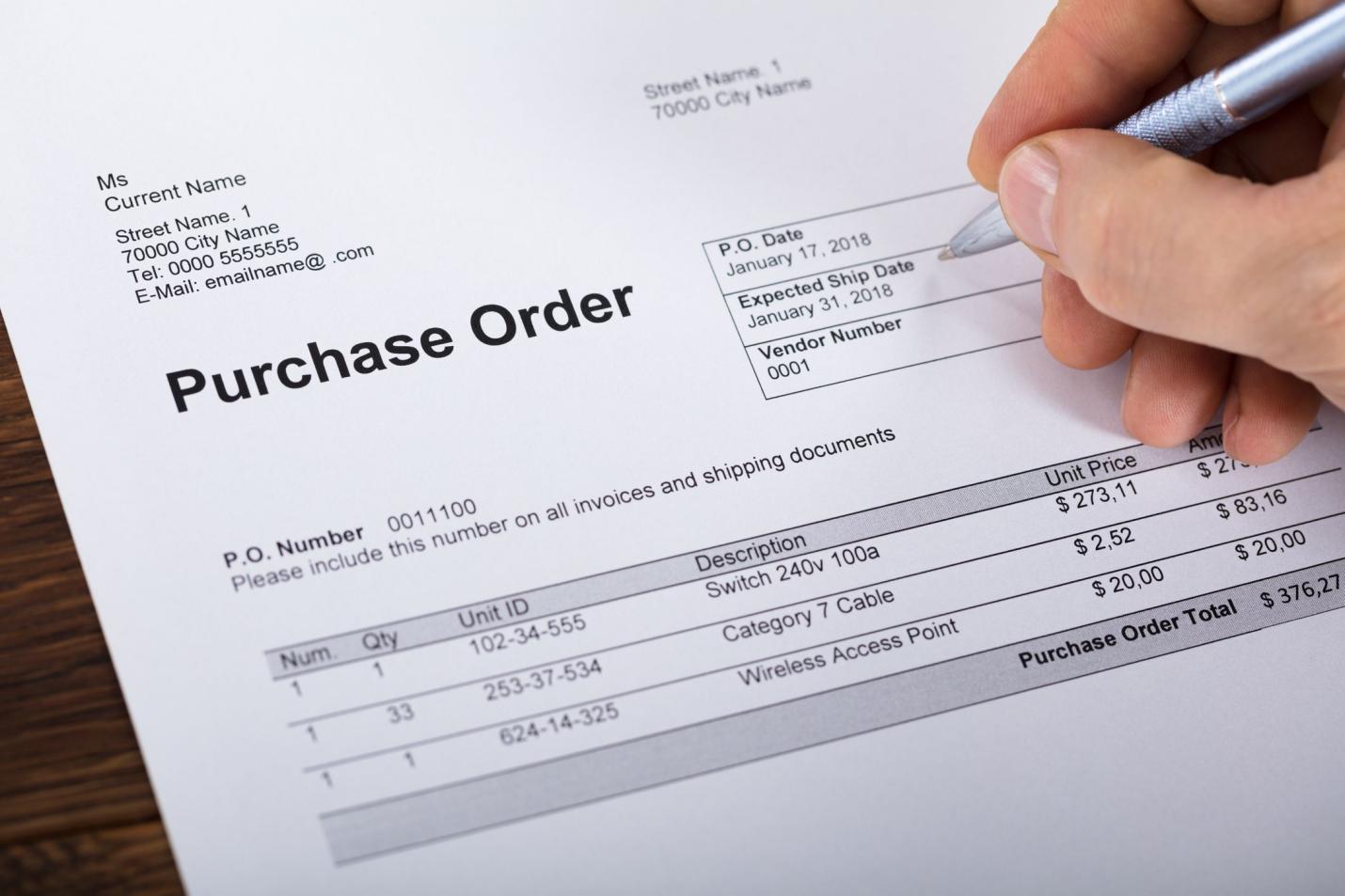

The time it takes from when an order is placed to when it is received is measured by order lead time. Take, for instance, an order placed by your online business on June 1 with an expected delivery date of June 15 from the supplier. Two weeks, or 14 days, is the estimated lead time for your purchase order under these conditions. Order placing, order confirmation, shipping notification, receipt of products, invoicing, and payments are all required within this POLT. For the PO to be performed precisely and on schedule, products must be readily available. Online merchants must meticulously arrange their production and manufacturing lag times. A delay in production inputs has the potential to compound the problem.

Predicting the Lead Time of an Order

External variables might throw your lead times off even if you take every precaution. Lead times can be impacted by several factors, including but not limited to the seasons, human error, and unexpected disruptions in the supply chain.

Seasonality

We discuss seasonality when discussing the ebb and flow of client demand throughout the year. In other words, seasonality is the pattern of increased demand experienced by businesses at certain times of the year. Some online retailers see a surge in business in the spring and summer, while others see it in the fall and winter. Your order processing times will be significantly impacted by seasonality whenever it happens. This is because it takes longer for suppliers to fulfill orders when they receive many buy orders all at once.

Human Errors

If you rely on manual processes or computations, human mistakes and accounting irregularities might creep into your business. In a nutshell, it's easy to underestimate your replenishment needs or miss deadlines when you rely on static spreadsheets (or other paper documentation).

This is because your data isn't being refreshed in real-time. Thus it doesn't represent the true state of your inventory. Incorporating automation (especially inventory management software) into your lead time estimates is crucial. They offer round-the-clock access to up-to-date information on product movement, which can greatly enhance the precision with which order lead time estimates are made.

Contamination Of The Supply Chain

Modern e-commerce stores, whether they like it or not, regularly deal with supply chain interruptions. In the past two years, companies worldwide have had to deal with longer order lead times due to a lack of raw materials, labor shortages, natural catastrophes, and transportation difficulties.

Even though it may be impossible to foresee some of these disruptions, you should think twice before making any new orders with your suppliers. Sufficient lead time for suppliers to complete orders and enough levels of safety stock in the warehouse have been cited as effective responses to problems in the supply chain. With this method, you may keep making sales despite significant shipment delays.

Expected Order Lead Times

What you sell, how far in advance you make orders, and where your suppliers are situated will all significantly affect the lead times you may anticipate. Your firm may experience longer lead times if you deal in a popular product sector with a fair degree of competition.

Your delivery date will also likely be pushed back a little if you deal with international suppliers or routinely submit your purchase orders at the last minute. The time it takes to fulfill an order might range from a few days to many months.

Special Considerations

For low-value or small-quantity commodities, a corporation can set up a two-bin inventory control system to automate the reordering process. When ordering critical inputs, a business must consider both shipping and order processing times.

For example, if you need to order supplies on a Friday, they cannot arrive until Monday, costing you two days. If raw materials are in short supply, production delays and quality issues might occur if suppliers have to go elsewhere to fill their orders.